Our extensive inventory includes a wide range of products from renowned brands, ensuring that you find the perfect equipment to elevate your listening experience.

Analog Relax

EX300 Phono Cartridge

EX300 adapted newly developed “IF adhesive” technology for stronger integration of the stylus and cantilever, also the body housing consists of high-grade walnut that is often used to the neck, back and sides of a guitar and is shaving out from the solid wood.

Adoption of newly developed “IF adhesive” stylus tip fixation for precise and powerful sound

Previously, no attention was paid to fixing the stylus tip and cantilever. It’s natural because it is a world where is invisible to the naked eye. However, it is an undeniable fact that considerable pressure has been applied on the fixed part of the stylus tip and cantilever over a long period of time during playing a record. Therefore, reviewing the fixed part of stylus tip and cantilever was the starting point of this time development of EX300. What we found during the test was that although it is micro level, there is adverse effect on the sound due to wobbling at the junction of the stylus and cantilever. And the result of trial-and-error, we have developed new adhesive material and bonding procedure of “IF adhesive”. IF adhesive is a new adhesive method in which very fine diamond particles are mixed with a special adhesive to fill the space between the stylus tip and the cantilever hole. By integrating the stylus tip and cantilever firmly, it is possible that the amount of information and the presence can be improved dramatically.

Tone Wood for musical instruments Solid walnut used for body

We also obsessed about the wood material of the body housing for this time too as other models. The body housing of the EX300 adopted carefully selected from solid walnut, which is the tone wood used for the guitar. By using beeswax derived from nature for finishing, a deep color peculiar to walnut is created, which makes you feel even more excited.

EX300 is suitable to payback any kind music category, it is characterized by sound precision and powerful sound reproduction with a solid foundation in the mid to low frequency range. It goes especially well with guitars made of the same wooden material.

Reed Tonearms

Reed 5T

Reed 5T is our first appearance in the tangential tonearm domain. Featuring unique design, innovative technological solutions and high quality, and dedicated to a true audio passionate, it is one of the most advanced tonearms we have ever made.

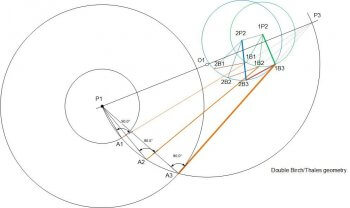

Reed 5T technically is a tangentially tracking pivoted tonearm. It’s working principle is based on Thales’ theorem (if the center of a triangle’s circumcircle lies on the triangle then the triangle is right, and the center of its circumcircle lies on its hypotenuse) and the rule, that given three non-collinear points, it is possible to draw only one circle that has finite radius and passes through all three. (Fig. 1)

Figure 1

P1, O1, P3 – Thales’ semicircle,

Angles P1-A1-P3, P1-A2-P3, P1-A3-P3 are 90 degrees each,

Segments A1B1 = A2B2= A3B3 represent length of a tonearm,

B – Tonearm vertical axis,

P2 represents a center of circle, drawn through three points – B1,B2 and B3 (tonearm rotation axis),

P3 – Linear Sensor Array,

BP3 – Laser beam.

Arm tube suspension system is similar to one used in Reed 2G tonearm, and the tonearm’s turning part is based on low noise thrust-sleeve bearing. For angular rotation of tonearm we designed and built limited rotation sectional torque motor. Tonearm’s position is controlled by laser and linear sensor array.

Reed 5T has user-replaceable arm tube – feature, which allows to change tonearm’s effective mass yourself. Tonearm also has VTA and azimuth adjustments.

Reed 5T has following advantages if compared with pivot tonearms:

Smaller moment of inertia,

No need for anti-skating mechanism,

Max tracking error is +/- 5 Minute of Angle (MOA). (Figure 2). Pivot tonearms usually have max tracking errors up to 1.5 deg.

Figure 2

Reed 5T’s advantages compared to other tangential tonearms:

Few times smaller moment of inertia,

No need for complicated additional devices (air compressor),

Compact and sleek design.

Effective mass in both vertical and horizontal directions is similar

Reed Tonearms

Reed 2G

Reed 2G is tonearm model, which merges the best features of Reed 2A and Reed 3Q tonearms and adds a few new ones.

Reed 2G is very easily adjusted and can be mounted to virtually any turntable with or without an adapter.

As other our tonearms, Reed 2G features 0.2 mm precision VTA adjustment and tonearm’s height can be adjusted from 28 mm to 48 mm.

Tonearm has cardanic bearing system: vertical axis has thrust rotation bearings and horizontal axis is based on thrust pivot bearings (a bit close to Reed 3P). Such bearing construction eliminates bearing wobbling, which has a great impact to the quality of the sound.

All Reed 2G tonearms have unique azimuth adjustment system, which allows implementing a tonearm with replaceable armwand. Replaceable armwand feature allows you to change tonearm effective length and effective mass with no hassle. For connecting the armwand and tonearm body, high quality LEMO connector is used.

As well as all our tonearms, Reed 2G has replaceable headshells.

Reed 2G can be wired with Finewire C37 cable or have a 5-pin DIN connector for a custom cabling solution.

Tonearm’s antiskating is magnetic and is similar to one used in Reed 3P tonearm.

Reed 2G with the laser option

Laser-enabled Reed 2G version continues tradition of Reed 3Q and helps audio enthusiasts to set up their systems using latest technology. Calibrated laser add-on, used in this tonearm version, allows user to adjust VTA and azimuth quickly and precisely.

Review:

"This is a sample review" - Kevin Gepaya

Reed Tonearms

Reed 3P

Reed 3P, among other features, like fine VTA adjustment on-the-fly, also has a unique possibility of adjusting azimuth while playing a record. An exciting thing about the azimuth adjuster is that during the adjustment process the cartridge “swings” around the needle tip, hence keeping all other tonearm parameters intact (you can see how it works by watching a short video).

Magnetic antiskating and some other features, used in Reed 3P, were developed in our Reed Mag prototype model*, which made its first appearance in Analog Forum 2011 Krefeld, Germany.

Another 3Ps innovation is its bearing system. Although tonearm bearing system can be considered as gimbal, it acts like unipivot one. However, major difference from unipivot system is that instead of a single pivot three pivots and both vertical and horizontal axis’ magnetic stabilizers are used. Such bearing system is as rigid as gimbal, but its friction coefficient is as low as in unipivot.

Again, if you are bored with this technical talk, it is enough to know that in Reed 3P you can setup most of the tonearm’s parameters (VTA, azimuth, antiskating) on the fly, and due to the very sensitive bearing system you will not miss the slightest music tones.

Reed 3P is acknowledged not only by its high quality sound, but also for it’s distinctive design. It convinced the international 30-member expert jury of the “red dot award: product design 2012” international design contest and received one of the coveted awards – red dot – in the “Entertainment technology and cameras” category. The red dot design award, held by Design Zentrum Nordrhein Westfalen (Germany) and with origins reaching back to the 1950s, has established itself internationally as one of the most appreciated quality seals for outstanding designs.

Also in July 2013 the German Design Council committees have nominated Reed 3P tonearm for the German Design Award 2014, Lifestyle category.

The German Design Award is an interna

tional premium prize, which successfully enhances the standing of both designers and companies. Its organizer, the German Design Council, has been representing and supporting the German design industry with its expertise in all questions relating to design for 60 years now. A nomination for the German Design Award on the occasion of the anniversary of the German Design Council is especially significant – it stands for 60 years of design culture.

Reed Tonearms

Reed 5A

Reed 5A tonearm introduced as angling- 90o -tangential-pivot-tonearm, it is based on Double Birch/Thales geometry and will complement our tangential tonearm lineup.

Below is the scheme of Double Birch/Thales geometry ( Fig.1). Tonearm geometry is optimized for minimal tracking error.

Operating principle of the tonearm is illustrated in:

https://www.youtube.com/watch?v=oIoHvCE9F0I

Fig. 1

P1, O1, P3 – Thales’ semicircle,

P1-A1-P3, P1-A2-P3, P1-A3-P3 angles are 90⁰ each,

A1,1B1 = A2,1B2= A3,1B3 segments represent tonearm length,

1B – vertical axis of the tonearm,

1P2 – center of the circle, which is drawn through three points -1B1,1B2,1B3,- axis of rotation of the back link component

2P2 – center of the circle, which is drawn through three points -2B1,2B2,2B3,- axis of rotation of the front link component

1B1,2B1 = 1B2,2B2 = 1B3,2B3 – tonearm lever.

Armtube suspension system is similar to the one used in Reed 3P tonearm.

Tonearm’s back link uses low-noise ceramic rolling bearings.

Lever uses low-noise ceramic rolling bearing and rests on the sapphire – molybdenum carbide thrust bearing.

Sapphire – molybdenum carbide thrust bearings are also used for tonearm’s front link, vertical and horizontal axes.

Tonearm has VTA and azimuth setup and can be configured with Reed or SME (universal headshell connector) headshells.

To make sure tonearm setup is precisely horizontal, tonearm has integrated level and horizontal plane adjuster.

Comparing to regular pivot tonearms, Reed 5A does not require antiskating and has much less absolute tracking error (max. tracking error is +/- 4 Minute of Angle (MOA) (Fig.2). Pivot tonearms – approx. 1.2 – 2.5 deg. (Fig.3).

Comparing to other tangential tonearms, Reed 5A does not require any additional devices to work (e.g. compressors, electronic controllers), is compact and can be easily mounted on a wide range of turntables.

Reed Tonearms

Reed 1H

Reed 1H is the latest addition to our entry level tonearm series. And, for the first time, we introduce carbon fiber as primary Reed 1H’s armwand material.

After a thorough research we found a way to make the carbon fiber armwand’s acoustic properties close to ones that normally are typical for the wood.

By using soft wood to damp the carbon fiber tube, our new armwand’s acoustic properties become considerably better than using carbon fiber alone, and can be compared to wooden armwands.

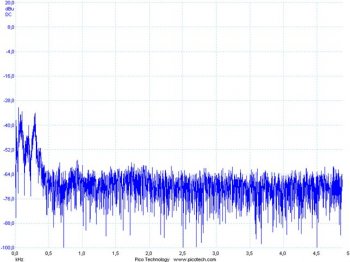

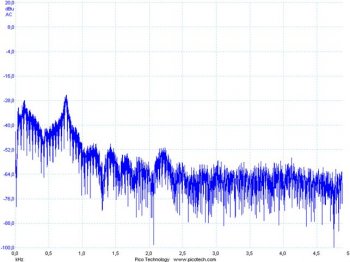

Differences between acoustical properties of damped and undamped carbon fiber wand are shown in Figures 1 and 2.

Figure 1. Damped carbon fiber.

Figure 2. Carbon fiber.

Reed 1H has a cardanic bearing system: vertical axis has thrust rotation bearings and horizontal axis is based on thrust pivot bearings (same concept as in Reed 3P). Such bearing construction eliminates wobbling of a bearing, which has a great impact on the quality of the sound.

Among other features, Reed 1H tonearm has azimuth adjustment, replaceable headshell and VTA adjustment. Tonearm height adjustment range is from 28mm to 48 mm. It is also easily tuned and can be mounted on most turntables out of the box or using an adapter.

Tonearm signal output is either 5 pin-DIN connector or Finewire 37 cables.

Antiskating: magnetic, similar to the one used in Reed 3P.

Reed Tonearms

Reed 2B

Our newest tonearm Reed 2B offers our users three new operating possibilities:

1) A possibility to use heavier cartridges, up to 35 grams. The low-friction, ceramic bearings are used in this tonearm;

2) Tonearm “2B” comes fully assembled; it is only needed to mount the tonearm and adjust settings like VTA, VTF, azimuth and anti-skating;

3) The anti-skating force can be easily changed independently at the beginning and end of the record. This feature is practical for all newer cartridges’ users, exceptionally because of a variety of the new cartridge’s stylus’ shapes causing different friction forces between the stylus and record groove.

Short theory.

As we already know, when a stylus rides in a groove, the friction force provides a forward force which is tangential to the record groove. (Fig.1. Anti-skating)

F = μN μ – coefficient of friction, N – stylus force (VTF).

Whereas the direction of this force F is displaced 90°+ α from the line between the pivot and the stylus O2-A, this force provides a clockwise moment M around the pivots O2 (Fig.1. Anti-skating), which tends to drag the stylus towards the spindle O1.

In case to avoid the force imbalance while the stylus bears against the inner groove wall, moment M should be eliminated completely at any position on the record. This moment can be expressed by the following equation:

While the F, L and D are constant factors, and R varies accordingly to the stylus’ position, moment M can be expressed as a function of R (Fig.2 Theoretical). Practically an experiment was executed to determine skating force at different points of a record. Instruments used for this test were: fully matte and smooth test vinyl and tonearm Reed 3P with a “Phasemation PP-2000MC” cartridge that was subjected to 1.9 grams vertical tracking force during testing (Fig 3. Practical). Differences in skating force are clearly noticeable at the beginning, middle and end of the record.

Theoretically, it is known that moment M can be eliminated by providing equal compensation in the opposite direction (-M). (Fig.1.). In most cases, M is applied as a constant force, therefore the side thrust is completely eliminated only at a few positions on the record. To conclude, a tonearm with adjustable anti-skating force depending on the position on the record (diameter) is highly demanded.

Tonearm “Reed 2B” has the possibility to control anti-skating force by adjusting two anti-skating regulation handles at any time while playing a record.

.jpg)

.jpg)